Stainless steel welding electrode is crucial when corrosion resistance and process cleanliness are critical. In industrial fabrication and maintenance, success isn't just about the quality of the plate or pipe.

The final result is also influenced by the selection of stainless welding electrode, weld design, heat control, and post-welding cleaning. This article provides a comprehensive understanding of the basics of materials and recommendations for welding electrodes for stainless steel commonly used in workshops and projects.

The main purpose of this guide is to help you select the right electrode, understand the behavior of stainless alloys, and implement proper post-weld cleaning practices.

Each section is written in practical language so that it can be directly applied to daily work.

View all stainless steel welding electrode products.

Table of Contents

ToggleWhat is Stainless Steel?

Stainless steel is an iron alloy with a minimum chromium content of around 10.5%. Chromium forms a passive layer that protects the surface from corrosion.

This alloy can be enhanced by adding nickel, molybdenum, manganese, silicon, niobium, and other elements as needed for the application.

The passive layer that is formed is thin but very stable and can renew itself when scratched.

Variations in composition produce families of stainless steels with different mechanical properties and chemical resistance.

Types of Stainless Steel

The main classification of stainless steels is based on their microstructure at room temperature. Each family has its own unique corrosion characteristics, mechanical properties, and welding behavior.

Austenitic Stainless Steel

Austenitic grades contain high levels of chromium and sufficient nickel to stabilize the austenite phase. These materials are nonmagnetic in solid solution and offer excellent corrosion resistance.

Easy to shape and weld

Has good toughness at low temperatures

Susceptible to hot cracking if ferrite number control is too low

Ferritic Stainless Steel

Ferritic alloys contain chromium with little or no nickel. Their microstructure is dominated by ferrite, making them magnetic and having a lower coefficient of expansion than austenitic alloys.

Corrosion resistance is quite good in mild environments.

The tendency to hydrogen cracking is lower than some austenites.

Toughness at low temperatures is not as high as austenitic

Martensitic Stainless Steel

The martensitic type contains higher levels of chromium and carbon. This material can be hardened through heat treatment to achieve high mechanical strength.

Suitable for knife applications and components that require hardness.

Lower corrosion resistance than austenitic and ferritic

Requires preheat and postheat control in certain welds

Duplex Stainless Steel

Duplex alloys combine austenite and ferrite phases in equal proportions. This combination provides higher strength and good corrosion resistance, especially in chloride-rich environments.

Resistant to crevice corrosion and pitting corrosion

Requires interpass control to prevent embrittlement

Has a wide application range for oil and gas as well as chemical processes

Advantages of Stainless Steel Material

The advantages of stainless steel lie in its combination of corrosion resistance, ease of cleaning, and stability over a wide temperature range. The naturally occurring passive layer of chromium makes maintenance simple and economical in the long run.

Resistance to water, steam and many chemicals

The surface is easy to clean making it suitable for the food and pharmaceutical industries.

Stable at certain high temperatures with controlled strength reduction

What is Stainless Steel Welding Electrode?

Stainless steel welding electrode is a filler material formulated so that the weld metal composition matches the expected behavior and corrosion resistance.

Pemilihan kawat mengikuti material dasar, lingkungan operasi, serta proses pengelasan yang digunakan seperti GTAW, GMAW, dan SMAW.

The low carbon content variant aims to suppress sensitization in the heat affected zone.

A choice of electrodes for connecting different materials is available to ensure a safe transition of properties.

Application of Stainless Steel Welding Electrode

Stainless steel welding electrode is used in many sectors due to its demanding cleanliness, durability, and process stability. Its applications include new projects, modifications, and repair work.

Food and beverage process piping, CIP equipment, pressure vessels

Chemical and petrochemical industry equipment, utility facilities, and handling of chloride media

Maintenance of palm oil mills, energy facilities, and household appliances made of stainless steel

Factors to Consider in Choosing Stainless Steel Welding Electrode

The success of a joint depends on the compatibility of the electrode with the work environment and the welding technique. The following factors should be considered before establishing specifications.

Compatibility of composition with base materials including the need for low carbon content

Operating environment such as presence of chloride, working temperature, and process media

The welding process used along with a protective gas mixture to keep the bead clean

Availability of electrode diameter and initial parameters that support welding position and thickness

Types of Stainless Steel Welding Electrode

This section summarizes common electrode series positioned for austenitic stainless steel applications. The L in the product name typically refers to a lower carbon content to help control sensitization.

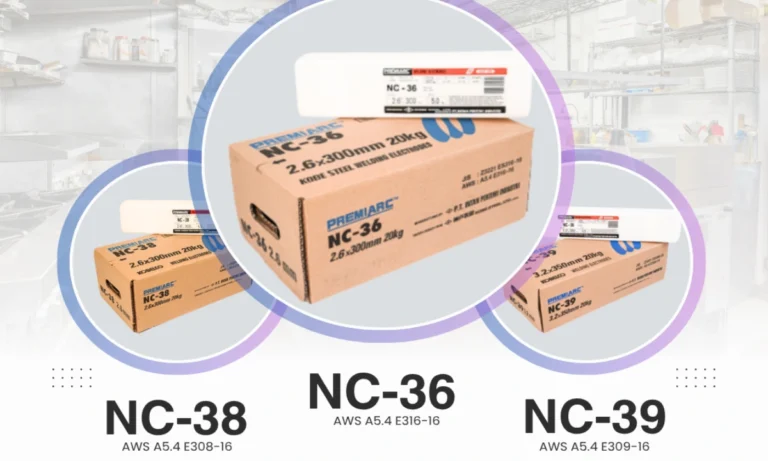

1. NC 36 Stainless Steel Welding Electrode

NC 36 is generally positioned for applications on 304 series stainless steels and their variants. This formulation emphasizes a balance between corrosion resistance and ease of processing in a variety of welding positions.

Suitable for pipes, thin vessels and joints that require high cleanliness.

Recommended for use with shielding gas that keeps the surface clean.

Check product NC 36 Stainless Steel Welding Electrode

2. NC 36L Stainless Steel Welding Electrode

NC 36L is designed with a low carbon content. Its primary purpose is to suppress the formation of chromium carbides in the heat-affected zone, thereby maintaining intergranular resistance.

The right choice for joints that will experience repeated heat cycles

Suitable for processes that require minimal cleaning after welding.

Check product NC 36L Stainless Steel Welding Electrode

3. NC 38 Stainless Steel Welding Electrode

NC 38 is used when transition properties between stainless steel and steels of different compositions are required. This formulation helps produce joints that are tolerant of differences in expansion coefficients and alloying element content.

Recommended on dissimilar joints or transition areas

Can be used as a base layer before filling with other electrodes that are equivalent to the main material.

Check product NC 38 Stainless Steel Welding Electrode

4. NC 38L Stainless Steel Welding Electrode

NC 38L maintains transitional performance with the added advantage of a low carbon content. This approach minimizes the risk of hot cracking and maintains the corrosion resistance of the joint over long-term service.

Suitable for transition piping and maintenance connections in process facilities

Supports buttering practices before core grafting

Check product NC 38L Stainless Steel Welding Electrode

5. NC 39 Stainless Steel Welding Electrode

NC 39 is selected when chloride-containing environments or when improved crevice corrosion resistance is required. Relevant alloying elements enhance performance in more aggressive media than the standard series.

Suitable for chemical process facilities, salt water utilities, and areas frequently exposed to condensate

Able to maintain a clean bead appearance with precise heat control

Check product NC 39 Stainless Steel Welding Electrode

6. NC 39L Stainless Steel Welding Electrode

The NC 39L is a low carbon variant of the series designed to withstand aggressive environments. This option helps maintain the stability of the passive layer after welding and extends the service life of the joint.

Recommended for thin vessels and pipes requiring high post-weld cleanliness

Can be combined with cleaning and passivation procedures for optimal corrosion quality.

Check product NC 39L Stainless Steel Welding Electrode

Post-Weld Cleaning and Passivation

After welding, stainless steel surfaces may exhibit heat discoloration and oxides, indicating changes in the protective layer. Proper cleaning aims to restore the passive chromium layer to maximize corrosion resistance.

General recommended steps

Remove spatter, slag and contaminants with a special stainless steel brush or fine abrasive.

Perform chemical cleaning according to product instructions to remove oxides and heat discoloration.

Apply passivation to strengthen the formation of the passive layer.

Rinse and dry thoroughly so that no residue remains.

Quality control points

Evaluation of visual appearance and surface uniformity

Use adequate shielding gas flow during the process to minimize oxidation.

Keep the interpass in a controlled range to keep the heat color low.

Conclusion

The decision to choose the right stainless steel welding electrode starts with understanding the material properties, work environment, and welding process used.

The NC series provides options that can cover needs ranging from work on the 304 series to transition needs and chloride environments.

Best results are achieved when electrode selection is combined with disciplined heat control, appropriate shielding gas, and consistent cleaning and passivation.

Need proven stainless steel welding electrode or want to discuss other welding consumable options? Our sales team is ready to guide you through recommendations and offers tailored to your project needs.

Contact us now for targeted welding solutions.

FAQs

1) What electrode do you use to weld stainless steel?

Depends on the grade: 304/304L uses 308L; 316/316L uses 316L; stainless steel to carbon steel connections uses 309L; difficult repairs can use 312. Adjust the TIG MIG SMAW process and diameter.

2) Can stainless steel be welded?

Yes. Select the appropriate grade of electrode, use the correct shielding gas, control the heat input, back-purge the pipe, then clean and passivation to maintain optimal corrosion resistance.

3) What is 309 stainless steel welding electrode for?

For joining dissimilar stainless steels to carbon or alloy steels, as well as buttering layers. The 309L variety suppresses sensitization and increases corrosion resistance in the HAZ area.