Before discussing the meaning of the E7016 electrode code in detail, first understand the basics of selecting electrodes and welding electrodes to match the material, thickness, position, and project standards. Use welding electrode selection reference as a starting point, then we will explain the meaning of the numbers and letters in E7016 and their application in field work.

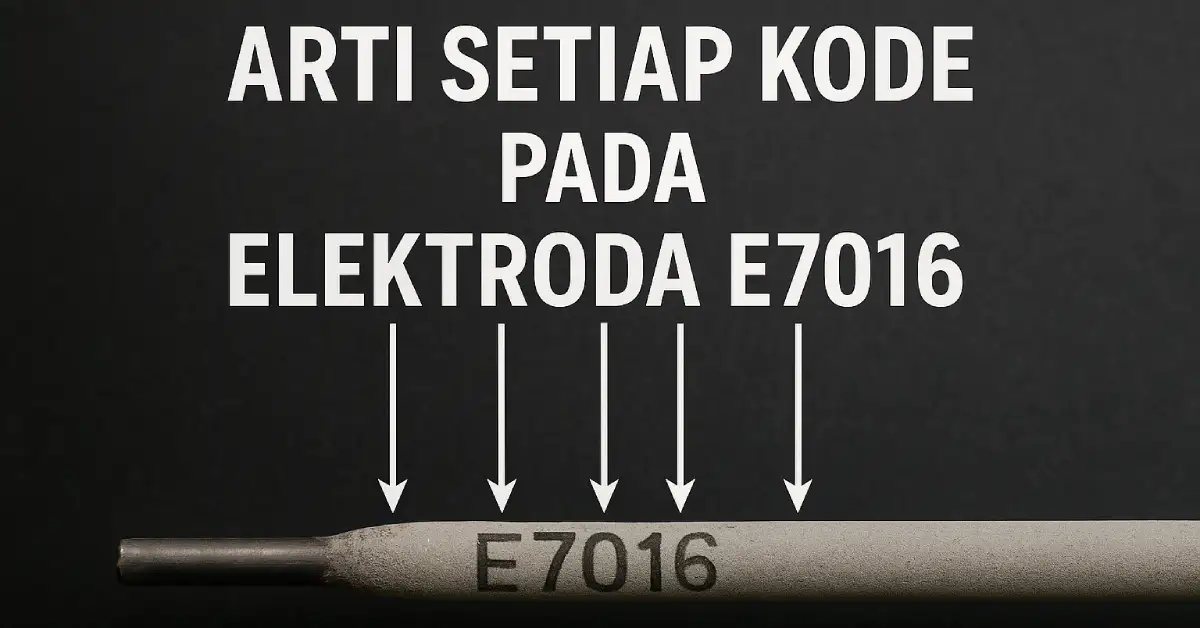

The meaning of the electrode code E7016 is an important thing that every welder, technician, and welding engineering student needs to understand.

This code is not just numbers and letters on the welding electrode rod, but rather complete instructions on the strength, welding position, and type of flux coating used.

By understanding the meaning of each number and letter on the E7016 electrode, a welder can determine the correct welding parameters and produce a strong, clean, and crack-resistant joint.

Quick Summary : What does electrode code E7016 mean?

This code indicates a welding electrode type with specific characteristics. "E" indicates an electrode for SMAW, "70" indicates a tensile strength of 70,000 psi, "1" means it can be used in all welding positions, and "6" indicates a low-hydrogen flux suitable for both AC and DC currents.

This article discusses the complete meaning of each code, characteristics, comparisons with other types, and tips for using them for optimal welding results.

Table of Contents

ToggleWhat is E7016 Welding Electrode?

The E7016 electrode is a type of SMAW welding electrode coated with basic flux or low hydrogen which used in the Shielded Metal Arc Welding (SMAW) process. This electrode is designed to produce strong, clean and crack-resistant welds.

In practice, E7016 is widely used for welding medium to high carbon steel, such as in building structures, bridges, high pressure pipes, and heavy industrial components.

Its advantages compared to common electrodes such as E6013 are denser weld results, high mechanical strength, and resistance to hydrogen cracking.

Meaning of Each Code on the E7016 Electrode

To better understand its function, here is an explanation of each part of the E7016 code:

Letter E – Indicates Electrode for SMAW

The letter “E” stands for Electrode, which means this welding electrode is used for the SMAW process or electric arc welding with a flux-coated electrode.

The flux on the electrode layer serves to protect the molten metal from air contamination and forms a slag layer after welding.

Number 70 – Tensile Strength of Weld Metal

The number “70” indicates that the welded metal has a tensile strength of 70,000 psi (480 MPa).

This means the welded joint can withstand tensile loads of up to 70,000 pounds per square inch before breaking. This is why E7016 is often used for heavy-duty structural work requiring strong, durable joints.

Number 1 – Welding Position

The number "1" indicates the electrode can be used in all welding positions, including flat, horizontal, vertical, and overhead. This flexibility makes it a popular choice in the field, eliminating the need to change electrode types for different positions.

Number 6 – Types of Flux and Electric Current

The number "6" indicates that E7016 has a low-hydrogen flux coating and can be used on both AC and DC currents with positive polarity (DC+). This basic flux coating helps reduce the risk of porosity and cracking, and produces a smooth weld bead with less slag removal.

In steel structure welding, this type is highly valued for its arc stability and solid finish.

Characteristics and Advantages of E7016 Electrodes

The E7016 electrode has several superior characteristics that make it popular among professional welders and heavy industry, including:

Produces high quality weld metal with good crack resistance

Slag is easy to clean and the weld surface looks smooth.

Provides a stable arc and a calm metal melt

Suitable for medium to high carbon steel

Can be used for high pressure welding or critical structures

Produces a small amount of spatter

In workshop practice, this electrode is often chosen because the results are consistent even on critical joints such as bridge frames or pressure vessels.

Comparison of E7016 vs E7018 vs E6013

To help you choose the right electrode, here's a comparison of three popular types:

| Electrode Type | Flux Coating Type | Tensile Strength | Weld Position | Main Characteristics | General Application |

|---|---|---|---|---|---|

| E7016 | Basic (Low Hydrogen) | 70.000 psi | All positions | Stable, smooth finish, crack resistant | Steel structure, pressure vessel |

| E7018 | Basic (Low Hydrogen dengan Fe Powder) | 70.000 psi | All positions | High metal deposits, easy to re-strike | Heavy construction, tanks, pipes |

| E6013 | Rutile (Medium Hydrogen) | 60.000 psi | All positions | Soft arc, easy to use | General fabrication, thin plate |

From the table above, it can be concluded that E7016 and E7018 are superior for structural work with high strength demands, while E6013 is more suitable for welding light and thin plates.

Also study function of LB and RB welding electrode to understand how the code naming of KOBELCO electrodes helps determine the choice of welding electrode according to the application.

Tips for Using E7016 Electrodes for Maximum Results

To get optimal welding results using E7016, pay attention to the following important things:

Make sure the electrode is dry before use

Store the electrode in a heating oven at a temperature of 250 to 300 degrees Celsius for 1 hour to remove moisture.

Moisture can cause porosity or cracks in the weld.Use a current according to the electrode diameter

For example, for a 3.2 mm diameter use a current of around 90 to 130 amperes.

Start at a medium current and then adjust based on the appearance of the bead.Maintain a short arc distance

An arc that is too long can result in rough welds and excessive spatter.

Use a small stringer bead for a neat finish.Use DC+ polarity for deeper penetration

DC+ produces a dense, strong bead, especially on vertical and overhead welds.Keep the metal surface clean

Clean it from rust, paint, and oil for cleaner welds and perfect fusion.

By following the steps above, the welding results using the E7016 electrode will be smoother, stronger, and have minimal defects.

Conclusion

The meaning of the E7016 electrode code reflects important information about strength, position, and flux type. The letter E indicates the electrode is for SMAW, the number 70 indicates a tensile strength of 70,000 psi, the number 1 means it can be used in all positions, and the number 6 indicates a low-hydrogen flux that can be used with AC or DC current.

Understanding the meaning of these codes helps welders choose the right electrode to produce a strong, high-quality weld joint.

Need neat and strong welds for your structure? Choose LB 52 welding electrode and LB 52U welding electrode. Stable low hydrogen electrode, easy to peel slag, and suitable for all positions. Available in diameters of 2.6 mm, 3.2 mm, and 4.0 mm to fit the parameters to the material thickness.

FAQ About E7016 Electrodes

What's the difference between E7016 and E7018?

E7018 has added iron powder in the flux layer, which increases the efficiency of the weld metal deposit. E7016 has a softer arc and lighter slag.

Can E7016 be used for pipe welding?

Yes, especially for structural joints that require high strength. However, E6010 or E7010 is often used for the root pass before E7016 is used for filling and capping.

What is the appropriate current for a 3.2 mm diameter E7016 electrode?

Generally between 90 and 130 amperes, depending on the welding position and the type of joint.