The term welding electrode encompasses SMAW electrodes, MIG/MAG wire, and TIG filler—the choice is determined by material, thickness, position, and project standards. This page summarizes the basics of welding electrode selection and KOBE product options for industrial needs.

Welding electrode is an additional material (filler metal) used to join two or more metals through a welding process. When welded, this electrode melts (or helps form a weld pool) thereby filling the joint gap and once solidified forms a strong metallurgical bond.

Selecting the right welding electrode will directly affect the strength of the joint, the appearance of the bead, work productivity, and even passing inspection tests on the project.

Therefore, it is important for welders and engineers to understand the types of welding electrode used, their classification standards, and their compatibility with base materials and industrial applications.

Table of Contents

ToggleIn general, welding electrode is differentiated by its welding process. Understanding this process helps you choose the most efficient electrode type and one that meets project standards.

SMAW (electrode/stick): Commonly used in field and construction work because it is flexible.

MIG/MAG (solid wire): Productive for fabrication, suitable for high-output workshop work.

TIG (filler rod): More precise heat control, neat results for certain materials and high quality requirements.

FCAW (flux-cored wire): More productive in certain applications, especially for high deposition requirements.

SAW (submerged arc): Generally for heavy fabrication with long and repetitive weld lines.

Choosing welding electrode can't be done simply by looking at the code or price. Each project has different requirements, depending on the material type, plate thickness, welding position, and the project owner's requirements. Here are some important factors to consider before selecting welding electrode.

The first thing you need to know is the type of base metal you are welding: whether it is carbon steel, high tensile steel, stainless steel, or cast iron.

For carbon steel and general work, electrodes with classifications such as E6013 or E6019 are widely used which are easy to use and suitable for a wide range of fabrication applications.

For heavy structures and constructions that require higher joint strength, low hydrogen welding electrodes with classifications such as E7016 or E7018 are usually chosen, which have better mechanical properties and toughness.

By understanding the base metal type, you can avoid problems such as cracks, brittle joints, or welds that are difficult to accept during inspection.

For piping and construction applications, understanding the E6010, E6013, E7016, and E7018 codes is essential. Also read meaning of the E7016 electrode code and what is AWS in welding.

Next, pay attention to the material thickness and the type of construction being carried out.

Thin plates require welding electrode that is easy to control and does not burn through easily, so that the heat input can be more controlled.

Thick plates and heavy structures require welding electrode with high tensile strength, good filling ability, and mechanical properties that can withstand long-term workloads and vibrations.

This information will help you select the most appropriate welding electrode diameter, welding current, and electrode type to achieve both productivity and joint quality.

For diameter and current limits based on thickness, see the guides welding electrode sizes for thick iron and welding electrode sizes for thin iron.

Each project also presents different challenges in terms of welding positions and processes. With the right combination of positions and processes, welders can work more efficiently, reduce rework, and produce a neater bead appearance.

If you use the SMAW process more, the guide SMAW welding electrode: definition, types, current, and welding position can be an additional reference.

For construction, oil & gas, power plant, and pipeline projects, the choice of welding electrode is usually not only a matter of whether it can be used or not, but must also meet the following requirements:

Standard classification, such as AWS or JIS specific.

If required, classification body approval or special requirements from the project owner.

Using welding electrode that meets standards will simplify the WPS/PQR process, mechanical testing, and quality audits in the field.

At INTIWI, the KOBE welding electrode range is designed to address these needs holistically—from versatile electrodes like RB-26 and MS-77 for general-purpose applications, to low-hydrogen electrodes like LB-26, LB-52, LB-52-18, and LB-52U for structures and pipes.

In addition, there is also a choice of welding electrode for hardfacing and stainless that can be tailored to your industry needs, so that engineering and welder teams can work more confidently with the support of the right product.

To help you choose welding electrode more appropriately according to field conditions, here are two guides that welders and engineers most often need:

KOBE welding electrode is a series of electrodes and welding electrode from KOBELCO that are produced and marketed in Indonesia through technical collaboration with PT. Intan Pertiwi Industri.

Each product is designed to provide consistent weld results, is easy to operate, and meets the quality demands of fabrication to construction projects.

| General needs | KOBE Welding Electrode Recommendations |

|---|---|

| General carbon steel fabrication & construction | RB-26, MS-77, B-17 |

| Heavy structure & construction | LB-26, LB-52, LB-52-18 |

| Vertical down pipeline | KOBE-6010 (root), KOBE-7010S (fill/cap), LB-52U (fill/cap) |

| Cast iron repair | CI-A1, CI-A2 |

| Heavy equipment hardfacing | HF-350, HF-500, HF-600 |

| Stainless 304/316 & dissimilar | NC-36/36L, NC-38/38L, NC-39/39L |

A comprehensive selection of KOBE welding electrodes is available for carbon steel, high tensile steel, stainless steel, hardfacing, and cast iron so your team can work quickly without sacrificing quality.

AWS A5.1 E6013

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Suitable for butt and fillet welding on thin plates. • Easy to use in all positions, including vertical downward welding. |

| Classification | AWS A 5.1 E6013 |

| Re-Drying Conditions | 70-100°Cx0.5-1h |

| Identification Color | 1st Black |

| Polarity | AC, DCEP, DCEN |

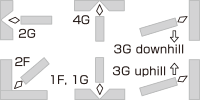

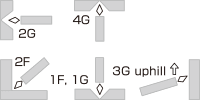

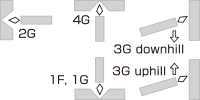

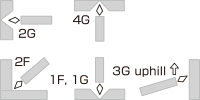

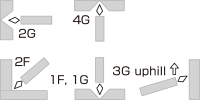

| Welding Position | 1F, 1G, 2F, 2G, 3G (up and down), 4G |

| Welding Electrode Size | 2.0 mm, 2.6 mm, 3.2 mm, 4.0 mm, 5.0 mm |

Want a quick consultation before ordering RB-26 welding electrode E6013? Contact our team.

Datasheet RB-26

AWS A5.1 E6013

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Stable arc ignition and minimal sparking. • Slag is easy to peel off, suitable for thin plates and general work, can be AC or DC. |

| Classification | AWS A 5.1 E6013 |

| Re-Drying Conditions | 70-100°Cx0.5-1h |

| Polarity | AC, DCEP, DCEN |

| Welding Position | 1F, 1G, 2F, 2G, 3G (up and down), 4G |

| Welding Electrode Size | 2.6 mm, 3.2 mm, 4.0 mm |

Ready to order MS-77 electrode for your project? Contact us.

Datasheet MS-77

AWS A5.1 E6019

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Suitable for butt and fillet welding on thin to thick plates (up to 20 mm). • Has good mechanical properties. |

| Classification | AWS A 5.1 E6019 |

| Re-Drying Conditions | 70-100°Cx0.5-1h |

| Identification Color | 1st Yellow |

| Polarity | AC, DCEP, DCEN |

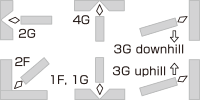

| Welding Position | 1F, 1G, 2F, 2G, 3G (up and down), 4G |

| Welding Electrode Size | 2.6 mm, 3.2 mm, 4.0 mm |

Want to consult before ordering Kobe B-17 welding electrode? Contact our team.

Datasheet B-17

AWS A5.1 E7016

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | Low hydrogen type electrode containing iron powder, provides high toughness and joint strength. |

| Classification | AWS A 5.1 E7016 |

| Re-Drying Conditions | 300-350°Cx0.5-1h |

| Identification Color | 1st Blue white |

| Polarity | AC, DCEP |

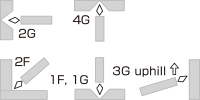

| Welding Position | 1F, 1G, 2F, 2G, 3G (up and down), 4G |

| Welding Electrode Size | 2.6 mm, 3.2 mm, 4.0 mm, 5.0 mm |

Ready to order kobe LB-26 electrode for your project? Contact us.

Datasheet LB-26

AWS A5.1 E7016

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Suitable for butt and fillet welding on heavy structures. • Has excellent mechanical properties. |

| Classification | AWS A 5.1 E7016 |

| Re-Drying Conditions | 300-350°Cx0.5-1h |

| Identification Color | 1st Blue white, 2nd White |

| Polarity | AC, DCEP |

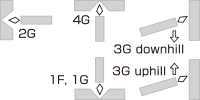

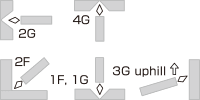

| Welding Position | 1F, 1G, 2F, 2G, 3G (up), 4G |

| Welding Electrode Size | 2.6 mm, 3.2 mm, 4.0 mm, 5.0 mm |

Discuss ordering Kobe LB-52 welding electrode with us.

Datasheet LB-52

AWS A5.1 E7018

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Suitable for butt and fillet welding on heavy structures. • Provides optimal performance with DCEP current. |

| Classification | AWS A 5.1 E7018 |

| Re-Drying Conditions | 300-350°Cx0.5-1h |

| Identification Color | 1st Blue white, 2nd Blue |

| Polarity | AC, DCEP |

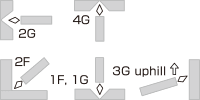

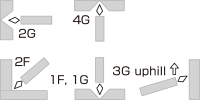

| Welding Position | 1F, 1G, 2F, 2G, 3G (up), 4G |

| Welding Electrode Size | 2.6 mm, 3.2 mm, 4.0 mm, 5.0 mm |

Request an official quotation Kobe LB-52-18 welding electrode today, contact us.

Datasheet LB-52-18

AWS A5.1 E7016

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Suitable for single-sided welding on pipes. • Offers excellent arc stability in single-sided welding at low currents. |

| Classification | AWS A 5.1 E7016 |

| Re-Drying Conditions | 300-350°Cx0.5-1h |

| Identification Color | 1st Blue white, 2nd Pink |

| Polarity | AC, DCEP |

| Welding Position | 1F, 1G, 2F, 2G, 3G (up), 4G |

| Welding Electrode Size | 2.6 mm, 3.2 mm, 4.0 mm, 5.0 mm |

Ready for production with Kobe LB-52U welding electrode? Contact us for orders.

Datasheet LB-52U

AWS A5.1 E6010

| Parameters | Details |

|---|---|

| Process | SMAW (Stick Electrode) |

| Key Features | • Suitable for welding butt joints on pipes. • Very convenient for vertical down welding. |

| Classification | AWS A 5.1 E6010 |

| Re-Drying Conditions | – |

| Identification Color | 1st Yellowish green |

| Polarity | DCEP |

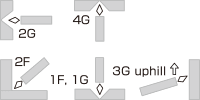

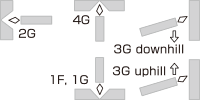

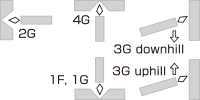

| Welding Position | 1F, 1G, 2F, 2G, 3G (down), 4G |

| Welding Electrode Size | 3.2 mm, 4.0 mm |

Need E6010 for pipes and repairs? KOBE 6010 welding electrode is available, contact us.

Datasheet KOBE-6010

AWS A5.5 E7010-P1

| Parameters | Details |

|---|---|

| Process | SMAW Stick Electrode |

| Classification | AWS A5.5 E7010 P1 |

| Key Features | Suitable for pipe butt welding. Very good for vertical downward welding. |

| Identification Color | 1st Brown, 2nd Black |

| Polarity | DCEP |

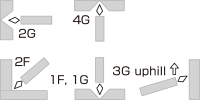

| Welding Position | 1F, 1G, 2G, 3G uphill, 3G downhill, 4G |

| Welding Electrode Sizes Available | 3.2 mm, 4.0 mm |

Ready to order KOBE 7010S welding electrode for your pipe project? Contact us.

Datasheet KOBE-7010S

AWS A5.15 ENi-CI

| Parameters | Details |

|---|---|

| Process | SMAW Stick Electrode |

| Classification | AWS A5.15 ENi-CI |

| Key Features | Nickel-based electrode for cast iron that provides strong bonds, crack-free welds, and is easy to machine. Recommended for repair of components made of gray cast iron, nodular cast iron, and malleable cast iron. |

| Identification Color | 1st Gold, 2nd Red |

| Polarity | AC, DCEP |

| Welding Position | 1G, 2G, 3G, 4G, 1F, 2F, 3F |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 70–100 °C |

Place your order Kobe CI-A1 welding electrode now, our team is ready to help.

Datasheet KOBE CI-A1

AWS A5.15 ENiFe-CI

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.15 ENiFe-CI |

| Key Features | Nickel-iron electrodes for welding gray and nodular cast iron, provide strong joints with low crack risk and are easy to machine. Suitable for repair of engine blocks, housings and industrial cast iron components. |

| Identification Color | 1st Gold, 2nd Pink |

| Polarity | AC, DCEP |

| Welding Position | 1G, 2G, 3G, 4G, 1F, 2F, 3F |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 70–100 °C |

Need Kobe CI-A2 welding electrode today? Contact us to order.

Datasheet KOBE CI-A2

JIS Z3251 DF2A-400-B

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | JIS Z3251 DF2A-400-B |

| Key Features | Fe-Cr based hardfacing electrode that produces a hard weld layer with high wear resistance to metal-soil friction. Offers a good combination of hardness and toughness for medium impact applications. |

| Identification Color | 1st Orange, 2nd Green |

| Polarity | AC, DCEP |

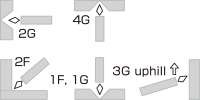

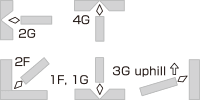

| Welding Position | 1F, 1G, 3G Uphil, 4G |

| Welding Electrode Sizes Available | 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 300–350 °C for 30–60 minutes before use |

| Nominal Hardness | Around Hv 350 (after air cooling) |

| Typical Use | Used for hard coatings on top rollers, sprockets, and bulldozer components that experience moderate to heavy friction. |

Order Kobe HF-350 welding electrode for your hardfacing, contact us.

Datasheet KOBE HF-350

JIS Z3251 DF2B-500-B

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | JIS Z3251 DF2B-500-B |

| Key Features | Fe–Cr based hardfacing electrode with nominal hardness around Hv 500 for high wear resistance in soil–rock friction. Abrasion-resistant martensitic coatings are suitable for light to moderate impact loads. A backing layer is recommended if the substrate is prone to cracking. |

| Identification Color | 1st Orange, 2nd Blue White |

| Polarity | AC, DCEP |

| Welding Position | 1G (flat), 1F (flat fillet) |

| Welding Electrode Sizes Available | 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 300–350 °C for 30–60 minutes before use |

| Nominal Hardness | Hv 500 |

| Typical Use | Bucket tips and bucket lips, sprockets and traction rollers, track links, dozer blades, friction surfaces of excavators and other heavy equipment requiring a hard, abrasion-resistant coating with limited impact. |

Ask for price and stock Kobe HF-500 welding electrode now, contact us.

Datasheet KOBE HF-500

JIS Z3251 DF2B-600-B

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | JIS Z3251 DF2B-600-B |

| Key Features | Iron chrome based hardfacing electrode with very high hardness around Hv 600. Forms a highly abrasion-resistant, non-machinable martensitic carbide layer and is recommended for low impact loads. |

| Identification Color | 1st Red, 2nd Red |

| Polarity | AC, DCEP |

| Welding Position | 1G (flat), 1F (flat fillet) |

| Welding Electrode Sizes Available | 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 300–350 °C for 30–60 minutes before use |

| Nominal Hardness | Hv 600 |

| Typical Use | Bucket lip and bucket wear sides, dozer cutting edges, ripper tips, chute liners, screw conveyor flights, mixer blades, and other abrasion-dominated surfaces with limited impact. |

Need Kobe HF-600 welding electrode today? Contact us to order.

Datasheet KOBE HF-600

AWS A5.4 E316-16

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.4 E316-16 |

| Key Features | Stainless steel electrodes for type 316 steel with high corrosion resistance to acids, sea water and industrial chemicals. Provides smooth and easily controlled welds in all positions. |

| Identification Color | 1st White |

| Polarity | AC, DCEP |

| Welding Position | 1G, 2G, 3G uphill, 4G, 1F, 2F |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 150–200 °C for 0.5–1 hour before use |

Place your order Kobe NC-36 welding electrode now, our team is ready to help.

Datasheet KOBE NC-36

AWS A5.4 E316L-16

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.4 E316L-16 |

| Key Features | Stainless steel electrodes for low carbon 316L steel. Provides excellent intergranular corrosion resistance in chemical, marine and high temperature environments. The bead results are smooth and easy to operate in various positions. |

| Identification Color | 1st Green |

| Polarity | AC, DCEP |

| Welding Position | 1F, 1G, 2F, 2G, 3G uphill, 4G |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 150–200 °C for 0.5–1 hour before use |

Need Kobe NC-36L welding electrode for corrosion-resistant stainless steel? Contact us.

Datasheet KOBE NC-36L

AWS A5.4 E308-16

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.4 E308-16 |

| Key Features | Stainless steel electrode for type 304 steel. Provides high corrosion resistance, good arc stability, and smooth bead results with easy slag removal. Suitable for fabrication and maintenance of tanks, pipes and chemical equipment. |

| Identification Color | 1st Yellow |

| Polarity | AC, DCEP |

| Welding Position | 1F, 1G, 2F, 2G, 3G uphill, 4G |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 150–200 °C for 0.5–1 hour before use |

Ask for prices and availability of Kobe NC-38 welding electrode today, contact us.

Datasheet KOBE NC-38

AWS A5.4 E308L-16

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.4 E308L-16 |

| Key Features | Stainless steel electrodes for type 304L steel with low carbon content that minimizes the risk of intergranular corrosion after welding. Provides smooth bead results, easy slag removal, and stable performance in all positions. |

| Identification Color | 1st Red |

| Polarity | AC, DCEP |

| Welding Position | 1F, 1G, 2F, 2G, 3G uphill, 4G |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 150–200 °C for 0.5–1 hour before use |

Submit your order Kobe NC-38L welding electrode now, our team responds quickly.

Datasheet KOBE NC-38L

AWS A5.4 E309-16

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.4 E309-16 |

| Key Features | Stainless steel electrodes for welding dissimilar metal joints such as carbon steel to stainless steel. It is also ideal as a buttering layer on ferritic steels before coating with other stainless steel electrodes. It produces smooth welds with high crack resistance. |

| Identification Color | 1st Black, 2nd White |

| Polarity | AC, DCEP |

| Welding Position | 1F, 1G, 2F, 2G, 3G uphill, 4G |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 150–200 °C for 0.5–1 hour before use |

Place your order Kobe NC-39 welding electrode now, contact our team.

Datasheet KOBE NC-39

AWS A5.4 E309L-16

| Parameters | Details |

|---|---|

| Welding Process | SMAW Stick Electrode |

| Classification | AWS A5.4 E309L-16 |

| Key Features | Low carbon stainless steel electrodes for dissimilar metal joints such as carbon steel to stainless steel. Suitable for backing layers on ferritic steels. Provides excellent corrosion and crack resistance with a smooth bead and easy slag removal. |

| Identification Color | 1st Yellow green, 2nd Blue white |

| Polarity | AC, DCEP |

| Welding Position | 1F, 1G, 2F, 2G, 3G uphill, 4G |

| Welding Electrode Sizes Available | 2.6 mm, 3.2 mm, 4.0 mm |

| Re-Drying Conditions | 150–200 °C for 0.5–1 hour before use |

Submit your welding electrode order Kobe NC-39L now, contact our team.

Datasheet KOBE NC-39L

KOBELCO's KOBE Welding Electrode is a precision-engineered consumable that delivers a highly stable arc, easy slag removal, and a neat bead; the result is a strong and consistent joint, reduced rework, increased productivity, controlled costs, and industry-class production quality.

Choose RB-26 (E6013) when you need easy starts and clean finishes on thin-medium slabs, use LB-52 (E7016) for structural strength and low hydrogen control that enhances toughness, and rely on KOBE-7010S (E7010) for deep-penetrating pipe/vertical-downs that speed progress without compromising quality.

Match the diameter to the thickness and position, then start at the manufacturer's recommended current range and increase gradually while monitoring bead shape, spatter, and penetration—this approach locks in heat control, stabilizes the weld pool, and ensures consistent results in the field.

Use 308/308L for 304/304L, 316L for more corrosive environments, and 309/309L for dissimilars or as a buffer against dilution—this combination improves corrosion resistance, maintains joint strength, and ensures long-term integrity according to WPS and service requirements.

Start with the material (carbon steel, low-alloy, stainless, cast iron), determine the working position & thickness, check the power source (AC/DC, polarity), and adjust to the service environment (corrosion, temperature, fatigue); select the relevant electrode type (E6013 for general purpose/clean finish, E7016 for toughness/low-hydrogen, 308L/316L/309L for stainless & dissimilar), match the diameter to the plate thickness, start in the manufacturer's recommended amperage range, perform a short test and gradually increase the current while monitoring the bead, spatter, and penetration; follow the WPS/PQR, consider preheat/PWHT if necessary, maintain dry storage, and consult your specific requirements for stable, strong, and long-lasting welds.

© 2026, PT. Intan Pertiwi Industri | Semua Hak Cipta Dilindungi.